From Material to Perfection

Your One-Stop Fastener Supply Chain Partner

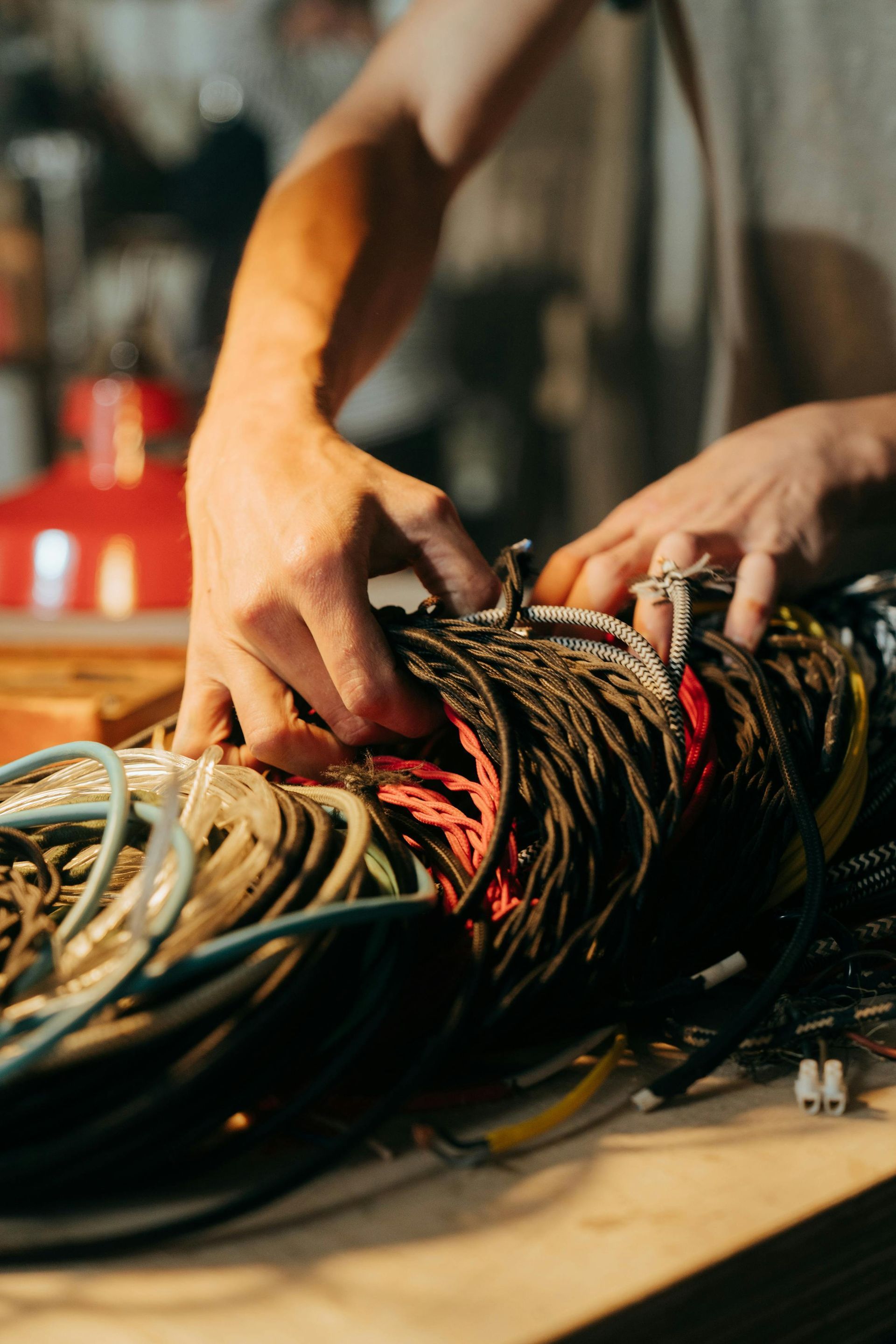

At YAOWAY, we go beyond supplying fasteners – we engineer full-scale solutions. As a complete fastener supply chain partner, we help customers transform ideas into finished screws by covering every production step, from mold design to wire selection, high-speed forming machines, on-site testing, and adjustment. Our hands-on testing and calibration service ensures every machine runs perfectly before full-scale production begins.

Bolt Forming Machine

High speed bolt forming machine, design and customized

Years of experience in the fastener and wire industry

Countries exported to across Asia, Europe, and the Americas

On-Time Delivery Rate across international shipments

Product Types, including self-drilling screws, machine screws, and customized fasteners

Our Story

We don’t just sell parts – YAOWAY deliver Screw Production Line that work from day one.

We have over 15 years of experience in the screw industry. By integrating the full supply chain of screw production, YAOWAY provides customers with a complete solution – from mold design, wire selection, and high-speed forming machines to final screw output.

Our service goes beyond parts:

We help customers

build and launch a screw production line from scratch. With in-house expertise in mold matching, machine integration, and on-site testing, we ensure that once equipment is delivered, it is

ready for mass production. This "turnkey solution" makes us stand out in the fastener field.

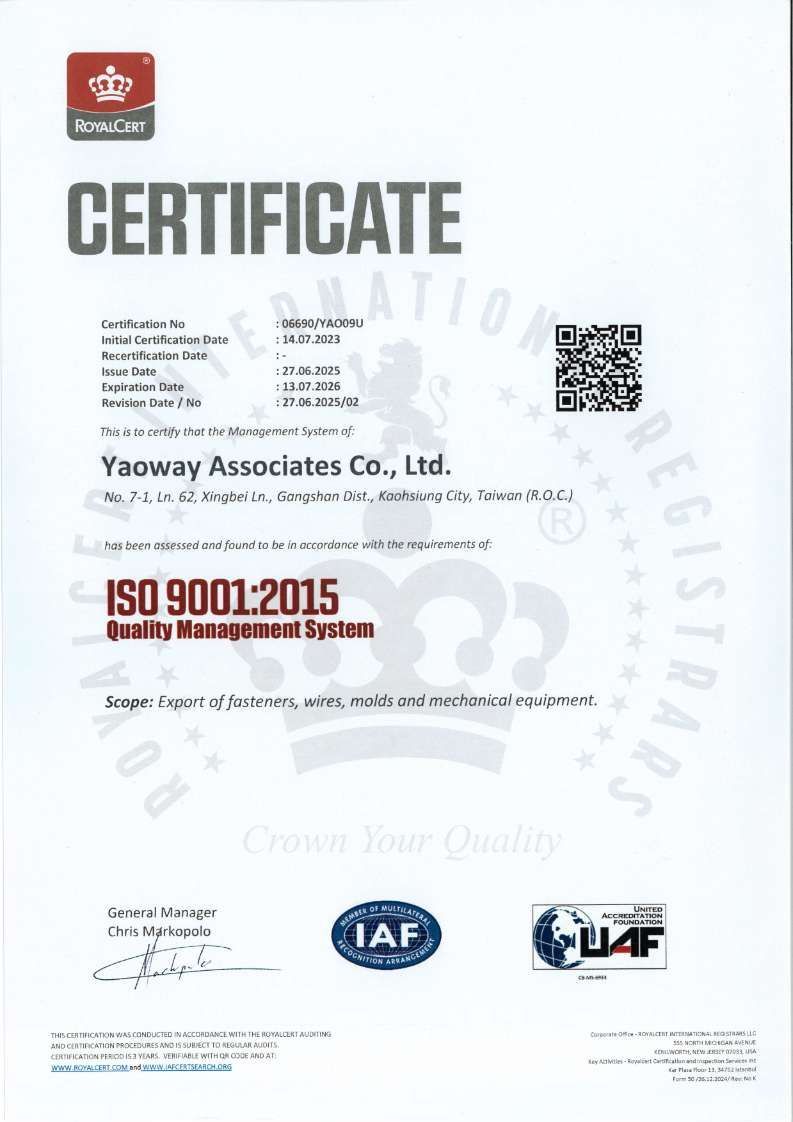

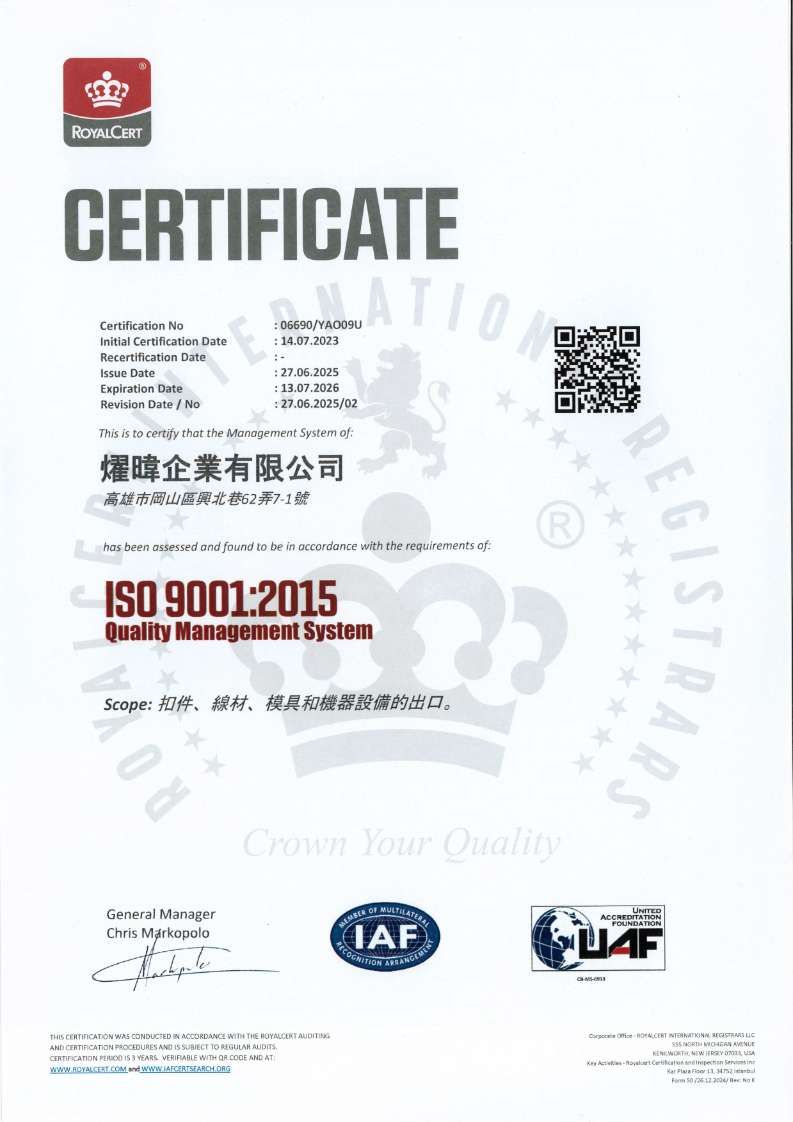

In addition, our long export experience combined with the services and resources we offer to clients from Taiwan and Asia, we’ve developed complete supply chain of screw production. As a result, we offer professional product development, mold design, and customized merchandises of special screw. Our office in Taiwan located with our partner Guan Ming Mould Co., Ltd. Together. Yaoway is the sole agency exported the mould from Guan Ming.

We specialist produced carbon steel and stainless steel fasteners for many years, also drawing steel wire under the big quantity demand then export oversea. Our main products involved from construction fastener , self tapping screws, self drillling screws, machine screws, also customized products in carbon steel and stainless steel material.